Beginning in 2021, BMW Group vehicles will get new sensing technology courtesy of Haifa, Israel-based tactile-data and virtual-sensing technology company Tactile Mobility (formerly MobiWize). The commercial partnership will result in embedding Tactile Mobility’s software into the group’s next-generation vehicles on a global scale.

The collaboration will mark one of the first commercial integrations by an OEM of tactile sensing technology and data, which will be used to enhance driving performance and detection of road conditions. Equipped with the technology, an OEM’s vehicles have the ability to analyze the road-surface attributes under their tires, enabling detection of road conditions and vehicle-dynamics management functions to enhance availability and performance.

Boaz Mizrachi, Tactile Mobility’s Cofounder and CTO, says that the partnership with the BMW Group for smart and future automated vehicles will show the commercial viability of tactile sensing technology. The long-term cooperation between the BMW Group and Tactile Mobility began through the BMW Startup Garage, the Venture Client unit of the BMW Group. Tactile Mobility’s dedicated team has been working toward this type of commercial integration for years, added Rani Plaut, Executive board member of Tactile Mobility.

The Tactile Mobility software suite uses a vehicle’s built-in, non-visual sensors to collect and analyze data about vehicle/road dynamics, such as available grip level, to signify specific vehicle/road traction limits. The company’s data services are based on a technology platform comprising two advanced software modules—in the vehicle and the cloud—that can be provided as a standalone or combined solution.

The embedded module can reside on one of the vehicle’s electronic control unit or on an aftermarket device connected to the vehicle CAN (controller area network) bus/OBD (onboard diagnostics) port. It runs proprietary algorithms and AI (artificial intelligence) to generate real-time actionable insights about the vehicle-road dynamics based on raw data ingested from multiple, existing, non-visual sensors.

Datasets from each vehicle are uploaded to the cloud and continuously crunched, using big data methodologies and machine learning. These analyses generate and continuously update two mathematical models, describing the critical factors that impact vehicle-road dynamics.

The suite includes VehicleDNA, an anonymized representation of each vehicle’s systems characteristics such as engine efficiency, braking efficiency, tire health, weight, and fuel consumption. Data are downloaded to each relevant vehicle, ensuring that the embedded software has the most updated and accurate context available for improved ongoing calculations and performance. It can also be commercialized with customers such as fleet managers and operators.

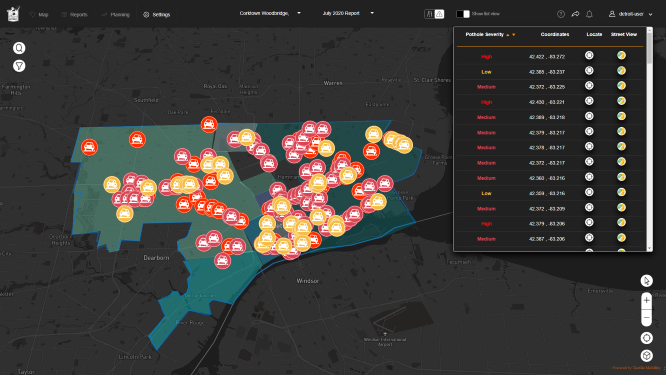

SurfaceDNA is a bundle of mapping layers of road attributes, conditions, and distresses that offers an in-depth view of driving environments to better anticipate road conditions ahead and preconfigure vehicle systems. It can model road features such as grades, banking, curvature, normalized grip levels, and location of hazards such as bumps, cracks, and potholes. Data are downloaded to vehicles, enabling them to prime the embedded software with insight on the road ahead, improving safety and user reaction time. This model is specifically valuable for third-parties such as mapping companies, road authorities, municipalities, fleet managers and owners, OEMs, and insurers.