At the IAA Mobility show in Munich, ZF will focus its exhibit on electric mobility and vehicle motion control technologies. The automotive supplier will highlight its electrification advancements with its Porsche Taycan-based EVbeat electric concept vehicle with a powertrain designed for maximum compactness, low weight, and maximum efficiency using a new electric motor without magnets.

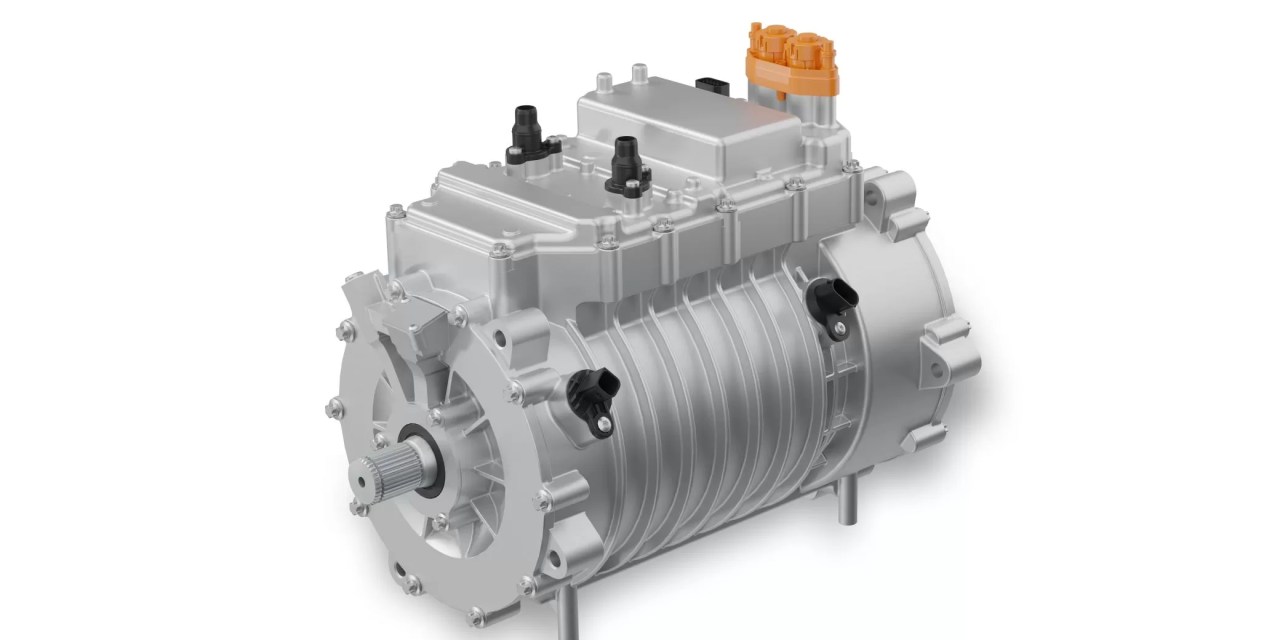

The advanced magnet-free concept of SESMs (separately excited synchronous motors) is an alternative to permanent-magnet synchronous machines (PSMs) most frequently used in EVs (electric vehicles) based on magnets that require rare earth materials for their production. The company’s I2SM (in-rotor inductive-excited synchronous motor) transmits energy for the magnetic field via an inductive exciter inside the rotor shaft.

This is said to make the motor more compact, with higher power and torque density. It eliminates the drag losses created in traditional PSM e-motors, enabling better efficiency at high speed.

“With this magnet-free e-motor without rare earth materials, we have another innovation with which we are consistently improving our electric drive portfolio to create even more sustainable, efficient, and resource-saving mobility,” said Dr. Holger Klein, CEO of ZF. “This is our guiding principle for all new products. And we currently see no competitor that masters this technology as well as ZF.”

Compared to more common SESM systems, the inductive exciter can reduce losses for the energy transmission into the rotor by 15%. In addition, the production CO2 footprint, which is higher with PSM e-motors due to magnets including rare earth materials, can be reduced by up to 50%.

“This uniquely compact electric motor without magnets is impressive evidence of our strategy to make e-drives more resource-efficient and sustainable, primarily through efficiency improvements,” said Stephan von Schuckmann, Member of the Board of Management of the ZF Group.

According to ZF, conventional SESMs typically require sliding or brush elements, forcing compromises. A dry installation space, not accessible for oil cooling and with additional seals, is necessary, which takes up around 90 mm (3.5 in) more space axially. So, manufacturers generally cannot flexibly vary between PSM and SESM variants without additional effort.

Compared with competing SESMs, the supplier’s solution features torque density significantly increased compared to the state-of-the-art thanks to an innovative rotor design. The “space-neutral” integration of the exciter into the rotor means that there are no axial space disadvantages. In addition, an increase in power density in the rotor improves performance.

Energy is transferred inductively, without mechanical contact, into the rotor, generating a magnetic field by means of coils, so the I2SM does not require any brush elements or slip rings. This area no longer needs to be kept dry by seals.

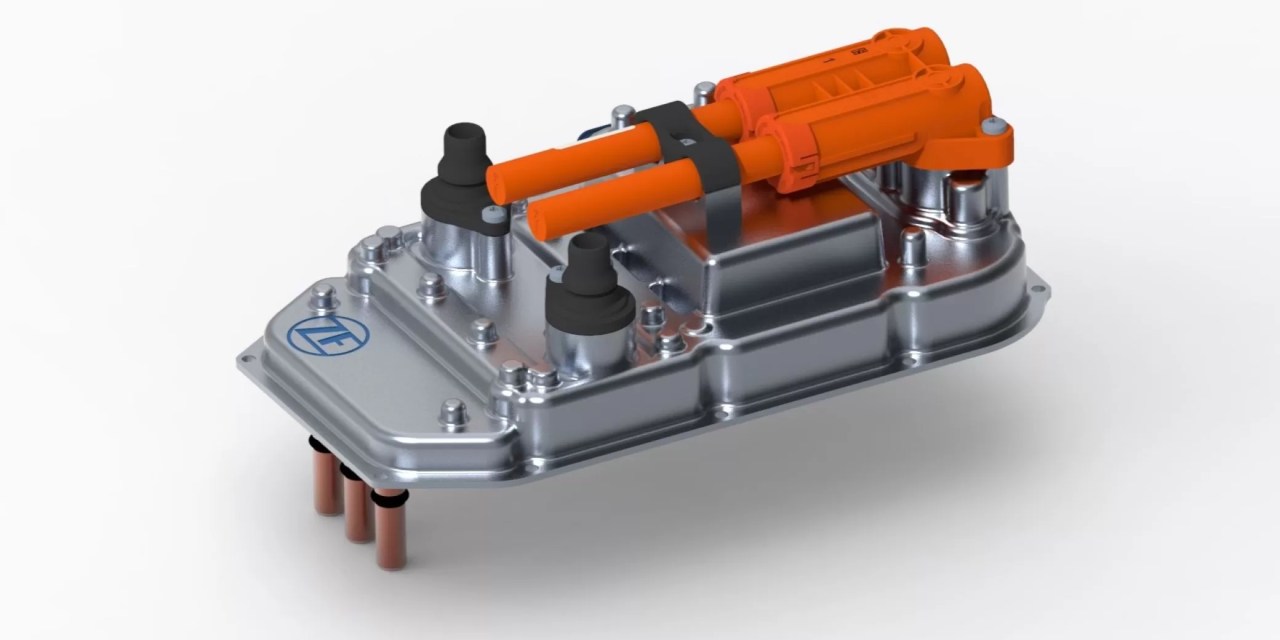

ZF plans to develop the I2SM technology to production maturity and offer it as an option within its own e-drive platform. Customers from the passenger car and commercial vehicle segments will be able to choose between 400- and 800-V architecture variants, the latter relying on silicon carbide chips in the power electronics.

In June, ZF presented its future modular 800-V EVSys800 drive that consists of silicon carbide power electronics, the electric motor, and a reduction gearbox in the EVbeat concept vehicle. The compact design and lightweight powertrain design in the concept vehicle has a maximum of 5200 N·m (3835 lb·ft) available on its rear axle. The high-torque-density solution for passenger cars features 70 N·m/kg and an electric motor continuous and peak power of 206 and 275 kW, respectively.

The drive saves 50 mm (2.0 in) in width thanks to the compact reduction gearbox and the electric motor’s patented “braided winding” technology, enabling coaxial space-saving on the drive axle. The EVSys800, normalized to the same output as the latest ZF 800-V series drive, has a total mass of 74 kg (163 lb), which is about 40 kg (88 lb) or 30% lighter.

- ZF I2SM e-motor without magnets and rare earths.

- ZF CEO Holger Klein with EVbeat earlier this year.

- ZF EVSys800 e-motor drive unit.

- ZF stator with new winding technique.

- ZF next-gen inverter.

- ZF coaxial reducer.