Parallel Systems, the autonomous battery-electric rail vehicle startup, has gotten a $4.4 million boost from the U.S. Department of Energy (DOE) in conjunction with its ARPA-E (Advanced Research Projects Agency-Energy initiative to advance high-potential, high-impact energy technologies. The agency will fund a 29-month advanced testing program with Parallel’s vehicles and a range of partners starting in the second quarter of 2022.

As part of the funding, Parallel’s autonomous freight system will be analyzed with DOE’s National Renewable Energy Laboratory (NREL) and the Rail Transportation and Engineering Center (RailTEC) at the University of Illinois, leveraging open-source railway modeling software. The overarching aim of the advanced testing program is to demonstrate three key innovations unique to Parallel’s system: overall vehicle stability, contact-based platooning, and energy efficiency.

“Our mission is to decarbonize freight by building a cleaner, automated rail future,” said Matt Soule, Co-Founder and CEO, of Parallel Systems. “The funds awarded from the Department of Energy will help us achieve our mission by supporting Parallel through our advanced testing phase. This critical step will enable us to move trucking freight to clean rail and accelerate the decarbonization of the entire freight industry.”

Parallel’s autonomous rail vehicles will be evaluated for track-worthiness in Pueblo, CO, at a state-of-the-art testing facility at Transportation Technology Center, Inc. (TTCI), a subsidiary of the American Association of Railroads. TTCI will collect data on how Parallel vehicles perform on the tracks in various conditions including dynamic stability in twist and roll, pitch and bounce, and yaw and sway. The tests will benchmark new vehicle dynamic performance against the requirements of traditional freight rail vehicles. It will also analyze Parallel’s contact-based platooning method and dynamics by providing further research on bumper designs, control logic, and the resultant reduction in energy.

NREL and RailTEC will collaborate to model Parallel’s vehicles and system performance, evaluating energy efficiency and environmental benefits. It will be one of the first technologies to be evaluated by NREL’s Advanced Locomotive Technology and Rail Infrastructure Optimization System (ALTRIOS) software. The ARPA-E-funded tool is designed to simulate and optimize energy conversion and storage dynamics, train dynamics, meet-pass planning (detailed train timetabling), and freight-demand-driven train scheduling.

ALTRIOS will help determine the optimal amount of energy Parallel needs to run and maintain its system, enabling the company to meet electric-charging demands. The software will also evaluate the merits of distributing the energy storage and investigate the improved network capacity and resilience achieved with self-propelled cars.

Out of stealth

Parallel came out of stealth mode in January of 2022, with the company unveiling its prototype and plans for a system to help overhaul the way the country approaches freight. See our coverage at “Parallel Systems aims to decarbonize and automate rail freight.”

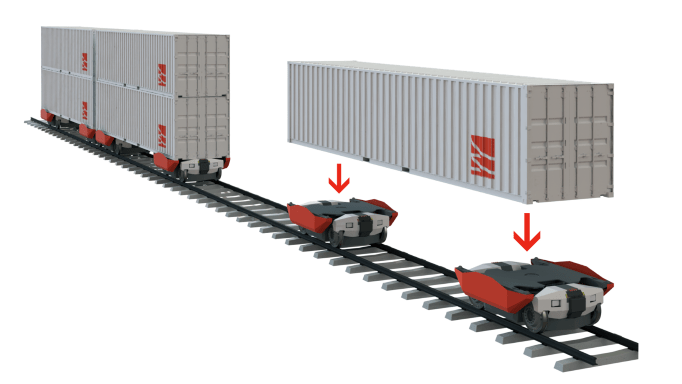

The company’s patent-pending vehicle architecture combines advanced software and hardware to increase the utilization of the U.S. railroad system. The zero-emissions railcars are individually powered and can work together to form platoons that reduce energy consumption or split off to multiple destinations while en route.

In an exclusive interview with Futurride last month, Soule explained the genesis of his company and its technology.

As he sees it, the rail industry does really well moving lots of volume at long distances. However, it struggles with serving lower volumes on shorter distance routes. He sees this as a major opportunity for his company, which is applying the combination of autonomous and electric technology to the challenge.

“What we’re doing is very unique in terms of the architecture,” said Soule. “Compared to self-driving cars and trucks, this is a dramatically simpler problem to solve. You’re not having the random interactions you’re having with other vehicles on the road, which is one of the biggest complications in successfully developing a self-driving car or truck.”

The overall philosophy is also unique. The company realized that the key to electrifying rail is to distribute the powertrain over the entire vehicle rather than concentrating it in the locomotive.

“A fundamental differentiator is that we’re moving individual containers rather than putting them on a vehicle that’s mechanically joined together—and pulling it,” said Soule. ”What’s even more unique is that we have two vehicles that collaborate together to move the vehicle; there’s not a spanning structure.”

Autonomy is a key enabler in making the battery-electric powertrain system work.

“We think the answer to make electrification suitable is to individually move [the railcars],” he said. “If we had a driver at every single vehicle, the economics would just be terrible. So, you need autonomy to make the powertrain architecture work.”

Accounting for variability

Another challenge for the industry is the size variability in containers, which are generally 20 or 40 ft long, but for domestic intermodal activities can be 53 ft long. Parallel Systems’ solution accommodates any size of container.

“What we asked ourselves is why don’t we let the container define the length of the car?” said Soule.

The company’s rail vehicles attach against the opposite ends of any container.

“We are individually moving the container,” said Soule. “We’re holding it similar to the way a key crane at a port would hold it.”

Efficiency advantages

The company was founded right before the pandemic, but the supply chain issues in restarting the economy are highlighting a lot of the issues the company is trying to address.

“A lot of ports, even before they became front-page news, have always strategically wanted to put more of their freight activities to rail rather than depend so much on trucks,” said Soule. “Some of the best ports out there, at least in the U.S., are doing maybe 20% of their container volume by rail and the other 80% is trucking.”

Compared with the trucking alternative, he says that the energy efficiency of rail is a big advantage.

For rail electrification, “less energy is required to move something from A to B meaning [fewer] batteries,” he explained. “There is more weight capability for carrying batteries too. It’s given us a lot of flexibility in how we’re solving the battery problem.”

He says that companies developing medium- to longer-haul electric truck solutions have a very difficult problem to solve.

“They need to find the intersection of a very, very low-cost battery to make sure the truck economics work, then the battery’s got to be very, very light to make that work as well,” he said. “And so that’s a big advantage that we have here.”

Unconventional platooning

In addition to the lower rolling resistance of steel wheels on rail, there are aerodynamics benefits for freight trains.

“Because all the freight volume is packed relatively close together, it’s actually better aerodynamically,” he said.

However, it could be better, as the current air gap between traditional railcars is about 20 ft.

“We wanted to do is close that air gap because it is ugly aerodynamically,” he added.

When platooning, a Parallel Systems’ train is not just drafting behind a lead vehicle but is pushing from the rear, with bumpers between vehicles.

“That pushing action helps keep those bumpers compressed and in contact and keeps that air gap small,” he said. “The advantage is that, when we platoon, we can be very close together; 18 in is about what we’re baselining right now.”

The company has a patent pending on this.

A more conventional platooning concept involves drafting behind a lead vehicle, which bears the brunt of the aerodynamic loads, that sets the range of the platoon because its battery is going to drain faster than the others.

“What I think is most important is that we are sharing the work mechanically through the platoon, which means that we get to our destination with about the same state of charge on every vehicle,” he explained.

A side benefit of the smaller air gap is security. A growing challenge for the industry is that, when trains are stopped, thieves are breaking into doors on container ends and unloading them as fast as they can. If discovered, by the time the engineer/conductor can get to the back of a conventional train, which can be a few miles long, thieves have already hijacked a few containers worth of cargo.

“You get better freight security with this approach because you can’t physically open the doors with our platooning 18-in gap,” he said.

What comes next

Parallel Systems is developing its second-generation vehicle, which its CEO says is a steppingstone to a future commercial vehicle.

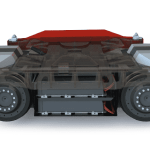

The vertically integrated company is using some off-the-shelf components, for example with its powertrain. However, the powertrain is highly customized to its vehicle.

“Right now we are fully owning the development of the vehicle, but we’re trying to be smart and use off-the-shelf parts from other industries,” he said. “We really want to tap into automotive supply chains, which we are right now.”

The company is fabricating its second-generation vehicle now and will start an advanced testing program this year to help get closer to commercialization. Company engineers will be demonstrating the perception system and integration with existing railroad operations.

Check out more on the company and its mission here and a product testing video here.

- Parallel Systems vehicle on the test track.

- Matt Soule is Co-Founder and CEO of Parallel Systems.

- Parallel Systems platoon double stack render.

- Parallel Systems vehicle render.

- Parallel Systems vehicle ghost view.